Understanding the Difference Between Double-Sided Boards and Multilayer Boards

2024-05-24

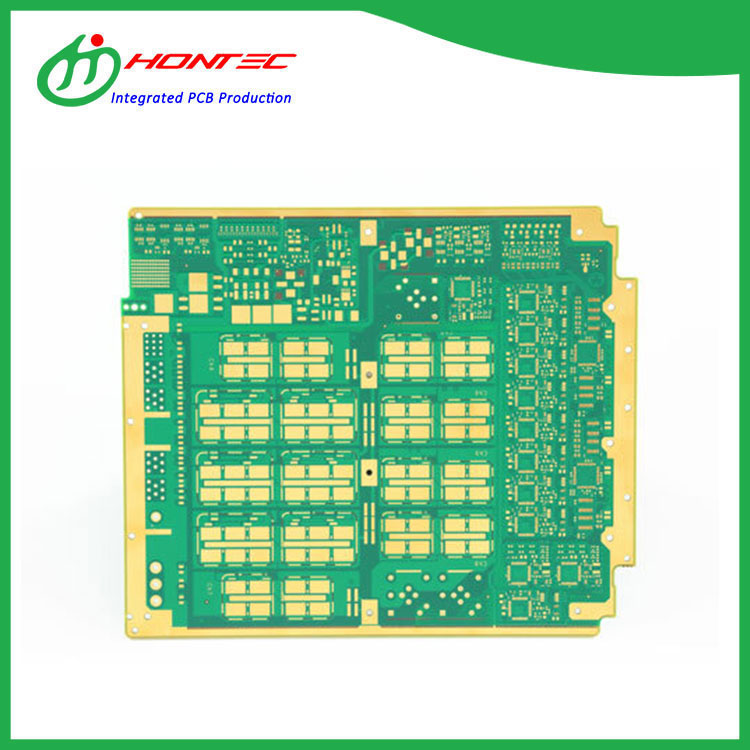

In the world of electronics, printed circuit boards (PCBs) are a crucial component of every device, serving as the foundation for all the electronic components to be mounted and interconnected. Among the various types of PCBs, double-sided boards and multilayer boards are two commonly used options. While they both have their unique advantages and applications, it's essential to understand the key differences between them.

What is a Double-Sided Board?

A double-sided board, also known as a double-sided PCB, is a type of PCB that has conductive traces and components mounted on both sides of the board. This design allows for increased component density and reduced board size, making it an ideal choice for compact and lightweight electronic devices.

The conductive layers on a double-sided board are typically made of copper, and they are separated by a non-conductive substrate material, such as FR-4 epoxy resin. The components are soldered directly onto the traces on both sides of the board, and the board is then enclosed in a protective coating to prevent damage and corrosion.

What is a Multilayer Board?

A multilayer board, on the other hand, consists of multiple layers of conductive and non-conductive materials stacked together. Each layer can have its own unique circuitry and components, and they are interconnected through vias or plated-through holes. This design allows for much more complex circuitry and increased component density compared to double-sided boards.

Multilayer boards are typically used in applications that require high-performance, high-density circuitry. They are common in devices such as computers, smartphones, and other advanced electronic systems. The conductive layers in a multilayer board are also made of copper, and they are separated by dielectric materials, such as epoxy resin or polyimide.

Key Differences

The main difference between double-sided boards and multilayer boards lies in their design and capabilities. Double-sided boards have conductive traces and components on both sides of a single substrate, while multilayer boards consist of multiple stacked layers of conductive and non-conductive materials.

Here are some key points to consider:

Component Density: Multilayer boards can achieve much higher component density compared to double-sided boards due to their stacked layer design. This allows for more complex circuitry and increased functionality in a smaller board size.

Circuit Complexity: Multilayer boards can support more complex circuitry due to their multiple layers of conductive traces. Double-sided boards, on the other hand, are limited to the circuitry that can be routed on the two surfaces.

Cost: Due to their increased complexity and manufacturing processes, multilayer boards tend to be more expensive than double-sided boards. However, the added functionality and performance they provide often justify the higher cost.

Application: Double-sided boards are commonly used in applications that require compact and lightweight designs, such as consumer electronics and portable devices. Multilayer boards, on the other hand, are typically used in more complex and demanding applications, such as computers, servers, and industrial equipment.

In summary, double-sided boards and multilayer boards both have their unique advantages and applications. Understanding the key differences between them can help you make an informed decision when selecting the right PCB for your project.