Timing Precision: Understanding the Production Cycle Time for Molding 38mm Caps in a 24-Cavity Mold

2024-01-17

Introduction:

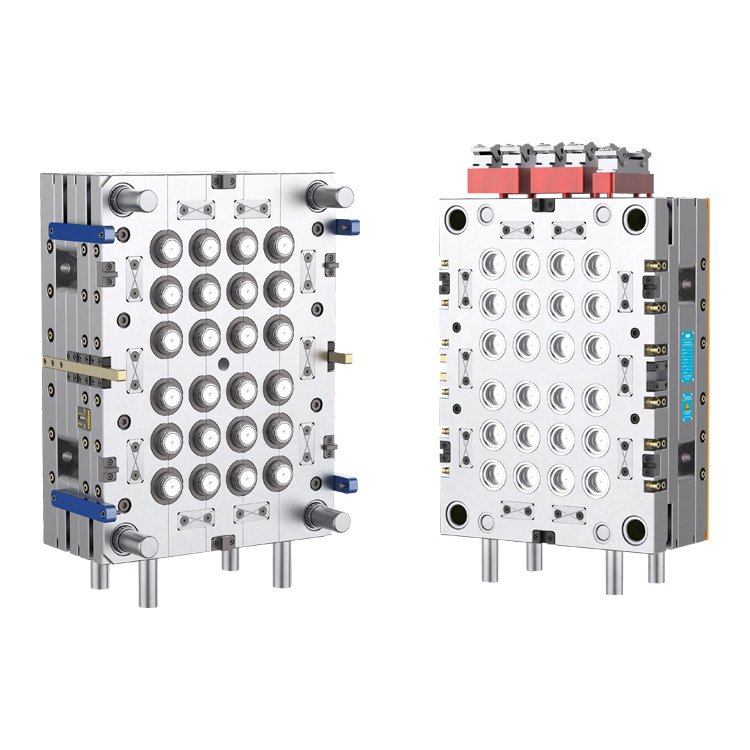

In the world of injection molding, efficiency is often measured by the cycle time – the duration it takes for a mold to complete one full production cycle. The production cycle time for molding 38mm caps in a 24-cavity mold is a critical factor that influences overall productivity and output. This blog explores the typical production cycle time and the factors that contribute to its optimization in the molding process.

1. Cycle Time Basics:

The production cycle time is the sum of various stages within the molding process, including injection, cooling, dwelling, and ejection. Understanding and optimizing each of these stages is essential to achieving an efficient overall cycle time.

2. Injection Time:

The injection time represents the duration it takes to fill all 24 cavities with molten material. This stage is influenced by factors such as material viscosity, injection pressure, and the complexity of the cap design. Advanced injection systems with precise control contribute to minimizing injection times.

3. Cooling Time:

Cooling time is a critical component of the cycle time and involves allowing the molded caps to solidify. The design of the mold, including cooling channels and strategic placement, plays a crucial role in achieving uniform cooling across all cavities.

4. Dwelling Time:

Dwelling time refers to the duration during which the molten material remains in the mold after injection and before ejection. It is crucial for ensuring that the caps achieve proper solidification and dimensional stability. Optimizing dwelling time contributes to overall efficiency.

5. Ejection Time:

Ejection time represents the duration required to remove the molded caps from the mold. The efficiency of the ejection system, including ejector pins or sleeves, influences the speed and reliability of this stage.

6. Automation and Robotics:

The integration of automation and robotics can significantly impact cycle times. Automated systems can streamline processes such as part removal, quality inspection, and packaging, reducing overall cycle times and enhancing efficiency.

7. Material Characteristics:

The properties of the molding material, including melt flow rate and cooling characteristics, directly influence cycle times. Selecting materials with favorable properties contributes to faster injection and cooling times.

8. Mold Design and Material:

The design of the mold and the materials used in its construction are pivotal factors. Efficient cooling systems, durable materials, and advanced mold designs contribute to shorter cycle times while maintaining high-quality standards.

9. Temperature Control:

Maintaining precise temperature control throughout the molding process is essential. Consistent temperatures contribute to predictable material behavior, faster cooling times, and overall cycle time reduction.

10. Quality Control Measures:

Incorporating quality control measures, such as sensors and cameras, within the molding process allows for real-time monitoring. Early detection of issues can prevent extended cycle times caused by defects or variations in the production process.

Conclusion:

Achieving an optimal production cycle time for molding 38mm caps in a 24-cavity mold requires a holistic approach that considers injection, cooling, dwelling, and ejection stages. Advanced technologies, precise control systems, and strategic design elements collectively contribute to minimizing cycle times while maintaining the high standards required in the production of caps. As the industry continues to evolve, the pursuit of efficiency in cycle times remains a central focus in advancing injection molding capabilities.