How to Use Bright Gold Thermal Lamination Film to Elevate Your Product Packaging

2024-09-09

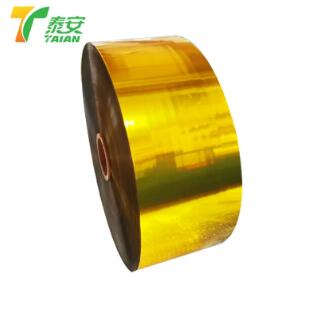

In today's competitive marketplace, product packaging plays a crucial role in capturing consumer attention and conveying brand value. One way to make packaging stand out is by using Bright Gold Thermal Lamination Film, which adds a luxurious and eye-catching finish to any product. This blog will guide you through the steps of using Bright Gold Thermal Lamination Film effectively in your packaging process, from selecting the right materials to ensuring a high-quality finish.

1. Understanding the Role of Bright Gold Thermal Lamination Film

Before diving into the application process, it’s essential to understand why Bright Gold Thermal Lamination Film is a game-changer for product packaging.

- Visual Impact: The reflective, metallic finish of bright gold laminates enhances the visual appeal of packaging, making products look more premium and enticing to customers. The shiny surface catches the light and draws attention, making it ideal for products in competitive retail environments.

- Added Protection: Aside from aesthetics, this laminate provides an extra layer of protection for the packaging. It guards against scratches, moisture, and fading, ensuring that your products remain in pristine condition through shipping, handling, and shelf display.

2. Selecting the Right Packaging Materials

The first step to successfully applying Bright Gold Thermal Lamination Film is choosing the right substrate for your packaging. The film works best on smooth, flat surfaces, but it’s compatible with a variety of materials.

- Paper and Cardboard: These are the most common substrates for thermal lamination. If you're designing packaging boxes, sleeves, or tags, make sure the paper or cardboard is thick enough to handle the lamination process without warping.

- Plastic: For high-end or luxury products, plastic packaging can also benefit from the application of gold lamination. The adhesive properties of the thermal film work well with most plastic surfaces, ensuring a strong bond and smooth finish.

3. Preparing for the Application Process

Once you have your packaging materials ready, you’ll need to set up your thermal laminating equipment. The lamination process involves applying heat and pressure to activate the adhesive on the film, which then bonds to the surface of the packaging material.

- Choose the Right Laminator: Depending on the size of your project, you may need a commercial-grade laminator. Ensure that your laminator can handle the size and thickness of the material you're laminating.

- Adjust the Temperature and Speed: Set the laminator to the correct temperature and speed based on the manufacturer's guidelines for the bright gold laminate. Too much heat can cause the film to warp or bubble, while too little heat may result in poor adhesion.

- Prepare the Materials: Make sure that the surface of the packaging is clean, free of dust, and dry before applying the laminate. Any debris or moisture can interfere with the bonding process and lead to imperfections.

4. Applying the Bright Gold Thermal Lamination Film

Now comes the exciting part – applying the Bright Gold Thermal Lamination Film to your packaging. Follow these steps for a successful application:

- Align the Film: Carefully align the lamination film with the packaging material to ensure it covers the surface evenly. Precision is key, especially for high-end packaging where aesthetics are crucial.

- Feed Through the Laminator: Slowly feed the material through the laminator, making sure it passes smoothly without any wrinkles or bubbles. It’s important to maintain consistent pressure and heat for a seamless finish.

- Trim the Excess Film: Once laminated, trim any excess film from the edges of the packaging to ensure a clean, professional look.

5. Quality Control and Finishing Touches

After the lamination process, inspect the packaging to ensure that the film has been applied smoothly and evenly. Look for any imperfections such as bubbles, wrinkles, or areas where the film may not have adhered properly.

- Smooth Finish: Run your hand over the laminated surface to check for any irregularities. A high-quality finish should be smooth and free of bubbles or streaks.

- Edge Sealing: If necessary, ensure that the edges of the laminated packaging are properly sealed to prevent peeling or fraying over time.

- Final Touches: Depending on the product, you can add additional elements like embossing, foil stamping, or spot UV coating to further enhance the packaging’s appearance.

6. Applications of Bright Gold Lamination in Packaging

Bright Gold Thermal Lamination Film is ideal for a wide range of packaging applications, especially for products that demand a premium look. Here are some examples:

- Luxury Goods: Perfumes, jewelry, and other luxury items benefit from the glamorous appeal of gold lamination, giving customers a sense of exclusivity.

- Gift Packaging: Special edition packaging or gift sets can be elevated with a bright gold finish, making them more appealing as presents.

- Food and Beverage: Gourmet foods, fine wines, and specialty beverages often use gold lamination to convey quality and craftsmanship.

Conclusion

Using Bright Gold Thermal Lamination Film is an excellent way to add a touch of luxury to your product packaging. Not only does it enhance the visual appeal, but it also offers protection against damage, ensuring that your products arrive at their destination in perfect condition. Whether you’re packaging luxury goods, promotional items, or consumer products, this laminate provides both style and durability that can set your brand apart.