Exploring the Key Characteristics of Petroleum Resin: Solubility, Viscosity, and Tackiness

2024-03-18

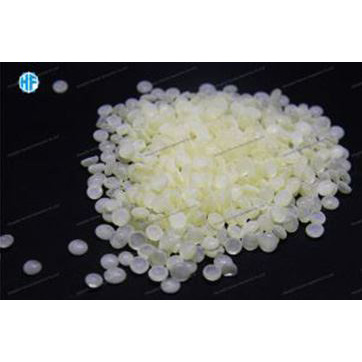

Petroleum resin, a versatile synthetic resin derived from petroleum feedstocks, possesses a unique set of characteristics that make it a valuable ingredient in various industries and applications. Among its notable properties are solubility, viscosity, and tackiness, each playing a crucial role in determining its performance and suitability for specific formulations. In this blog, we'll delve into the key characteristics of petroleum resin in terms of solubility, viscosity, and tackiness, and their significance in different applications.

Solubility:

Petroleum resin exhibits excellent solubility in a wide range of solvents, including hydrocarbons, alcohols, and esters. This high solubility allows petroleum resin to dissolve readily in liquid carriers, facilitating its incorporation into various formulations such as adhesives, coatings, and inks. The solubility of petroleum resin contributes to its compatibility with other materials, ensuring uniform dispersion and homogeneous blends. Additionally, its solubility enables efficient application and processing, leading to consistent results and enhanced performance in finished products.

Viscosity:

Viscosity refers to the resistance of a fluid to flow, and petroleum resin exhibits a range of viscosity levels depending on its molecular weight and formulation. Low-viscosity petroleum resins flow more easily and have a thinner consistency, making them suitable for applications requiring fast drying times and easy application, such as printing inks and coatings. On the other hand, high-viscosity petroleum resins have a thicker consistency and provide enhanced tackiness and adhesive strength, making them ideal for applications like hot-melt adhesives and sealants. The viscosity of petroleum resin can be tailored to meet specific application requirements, providing flexibility and versatility in formulation design.

Tackiness:

Tackiness refers to the stickiness or adhesive quality of a material, and petroleum resin exhibits excellent tackiness properties that are essential in adhesive formulations. As a tackifier, petroleum resin enhances the adhesive strength and bonding properties of adhesives and sealants, ensuring secure adhesion to various substrates. The tackiness of petroleum resin contributes to initial grab and holding power, allowing adhesives to form strong bonds quickly upon application. Additionally, petroleum resin-based adhesives exhibit good tack retention over time, maintaining their adhesive properties even under challenging environmental conditions such as heat, humidity, and cold temperatures.

Significance in Applications:

- Adhesives and Sealants: The solubility, viscosity, and tackiness of petroleum resin play crucial roles in formulating adhesives and sealants with the desired bonding strength, application properties, and performance characteristics.

- Coatings and Inks: In coatings and inks, the solubility of petroleum resin ensures uniform dispersion and consistent film formation, while viscosity control enables precise application and coating thickness. Tackiness contributes to adhesion and film integrity, enhancing the durability and longevity of the coating or ink.

- Rubber Compounding: In rubber compounding, the solubility of petroleum resin aids in dispersion and blending with rubber polymers, while viscosity control enables proper processing and compounding. Tackiness enhances the bonding strength and reinforcement of rubber compounds, improving adhesion to substrates and overall performance.

Conclusion:

The key characteristics of solubility, viscosity, and tackiness make petroleum resin a versatile and indispensable ingredient in various industries and applications. Whether in adhesives, coatings, inks, or rubber compounds, petroleum resin's unique properties contribute to enhanced performance, application versatility, and product durability. By understanding and leveraging these key characteristics, formulators can tailor petroleum resin-based formulations to meet specific application requirements, driving innovation and efficiency in modern manufacturing processes.