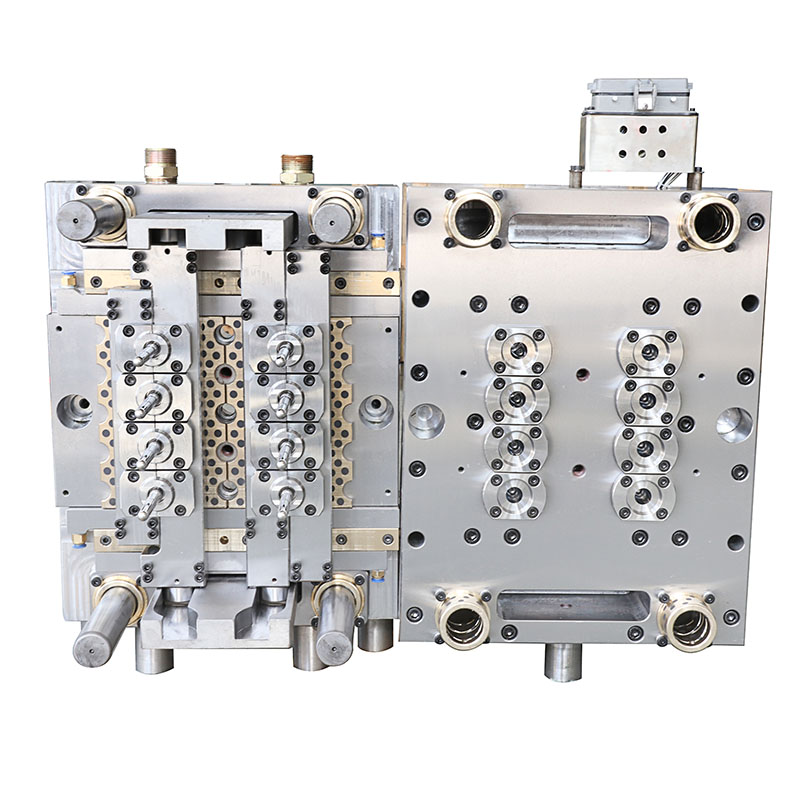

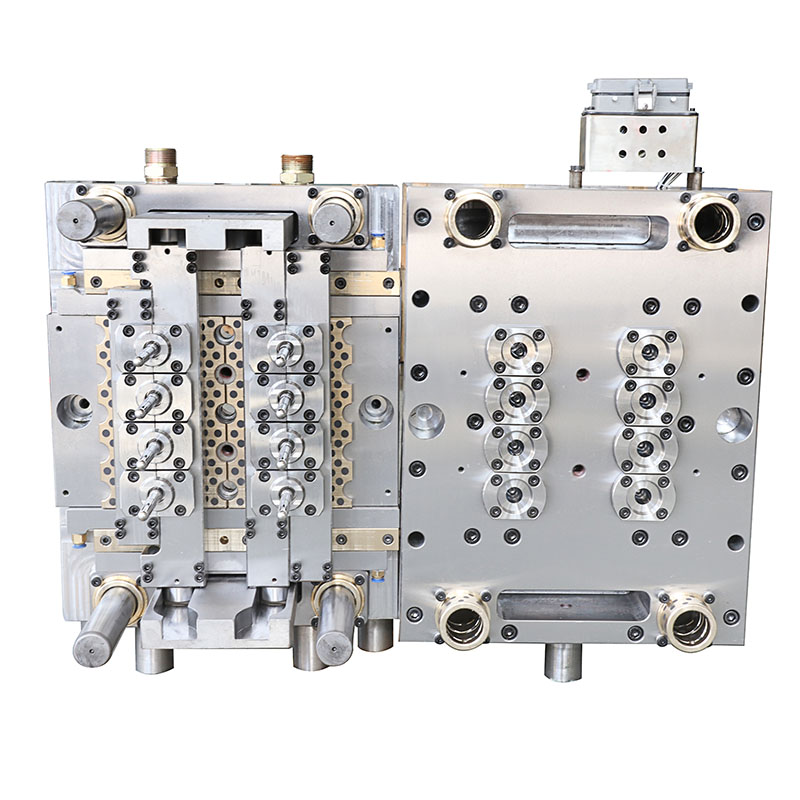

8 Cavity Hot Ruuner PET Preform Mould Valve Gate

An 8-cavity hot runner PET preform mold with a valve gate system is a specialized mold used for manufacturing PET (polyethylene terephthalate) preforms, which are widely used in the production of plastic bottles and containers. Here's a breakdown of the key components and features:1. Cavity Conf......

Send Inquiry

Product Description

An 8-cavity hot runner PET preform mold with a valve gate system is a specialized mold used for manufacturing PET (polyethylene terephthalate) preforms, which are widely used in the production of plastic bottles and containers. Here's a breakdown of the key components and features:

1. Cavity Configuration: The mold is designed with 8 individual cavities, allowing for the simultaneous production of 8 preforms in each molding cycle. This increases production efficiency and output compared to molds with fewer cavities.

2. Hot Runner System: The mold incorporates a hot runner system, which is a series of heated channels that deliver molten plastic directly to each cavity. The hot runner system helps maintain the desired temperature of the plastic, ensuring consistent preform quality and reducing material waste.

3. PET Material: PET is a common thermoplastic polymer used in the production of preforms for bottle manufacturing. It offers excellent clarity, strength, and barrier properties. The mold is specifically designed to work with PET material.

4. Valve Gate System: The valve gate system is employed in this mold to control the flow of molten plastic into each cavity. The valve gates act as shut-off nozzles, opening and closing to allow precise control over the injection process. This helps minimize gate vestige, reduce part defects, and optimize gate quality.

5. High Precision and Quality: The mold is manufactured with high precision to ensure accurate dimensions and consistent preform quality. This is crucial for achieving uniform wall thickness, proper weight distribution, and maintaining the desired characteristics of the final plastic bottle.

6. Cooling System: Efficient cooling channels are integrated into the mold to rapidly cool the preforms and shorten the cycle time. Proper cooling is essential for achieving optimal cycle times and ensuring the structural integrity of the preforms.

7. Ejection System: The mold is equipped with an ejection system to safely remove the molded preforms from the cavities once they have solidified. This can involve the use of ejector pins, sleeves, or other mechanisms to facilitate easy and reliable ejection.

8. Design and Manufacturing Expertise: Designing and manufacturing a high-quality mold requires expertise and experience in mold making. Molds need to be carefully engineered to withstand the high pressures and temperatures of the injection molding process while maintaining precise control over the plastic flow.

It's worth noting that the specific design and features of a Preform mold can vary based on manufacturer, application requirements, and customization options. When considering a mold, it's important to consult with mold manufacturers or experts to ensure that the mold design aligns with your specific production needs and quality standards.